Industry 4.0

Future-Ready Automation, Built on Industry 4.0 Principles

Get A Free Consultation

What is Industry 4.0?

Industry 4.0 is about more than just connected sensors or smart machines — it’s a shift in how industrial operations are planned, executed, and improved. It brings IT and OT systems together to deliver real-time visibility, actionable data, and better business decisions.

Principles of Industry 4.0

Real-Time Data Visibility

Access to live production and performance data at all levels of the business metrics for faster, more informed decision-making.

Business-Aligned Transformation

A digital strategy that is led from the top, and engages and includes all levels of the organisation. True transformation aligns people, processes, and technology around a shared direction.

Seamless System Integration

Connecting assets, software and people across both operations and enterprise systems. Bridging the gap between OT and IT unlocks shared context, consistent data, and unified visibility across the business.

Digital Supply Chain Integration

Connecting suppliers, manufacturers, and customers in real-time for better forecasting, order tracking, and production alignment.

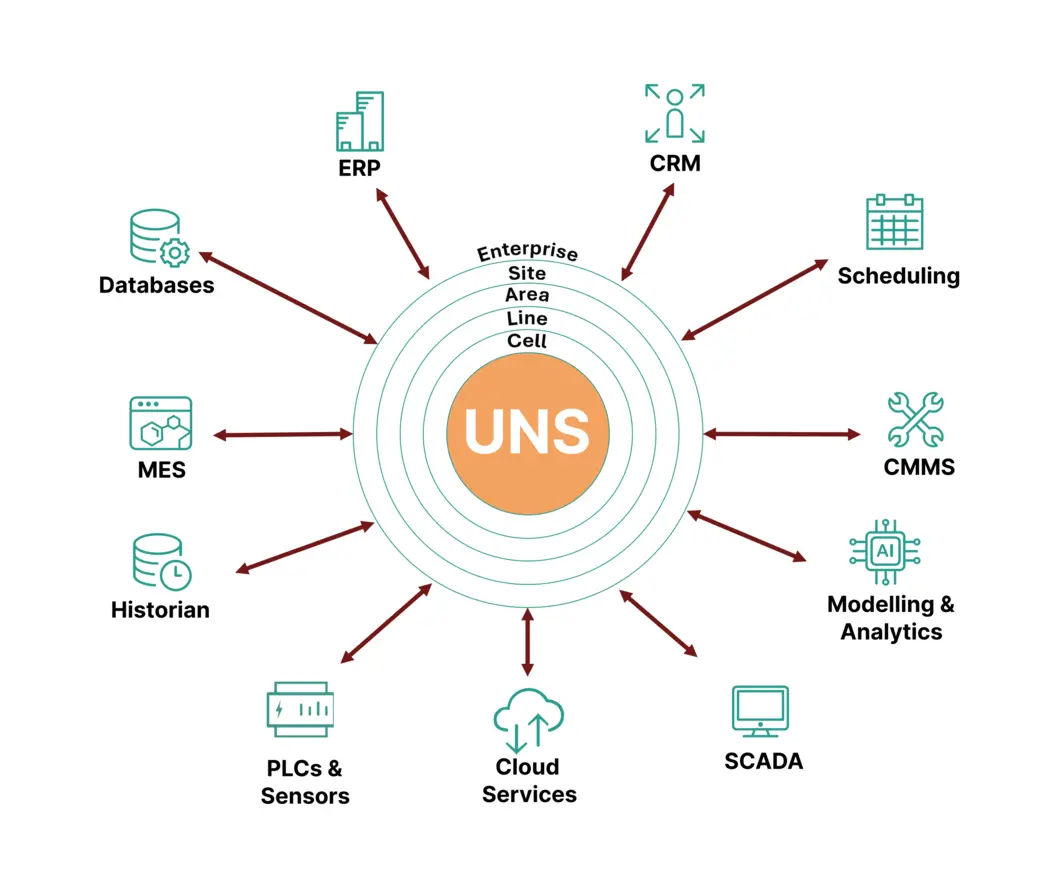

Unified, Scalable Data Architecture

Modern data architectures like Unified Namespace (UNS) that standardise industrial and enterprise data. This creates a single source of truth for the current state of your entire business.

Data-Driven Optimisation

Using analytics, AI modelling, and machine learning to uncover inefficiencies and continuously improve.

Keep it simple, stupid...

Industry 4.0 doesn’t have to be complex

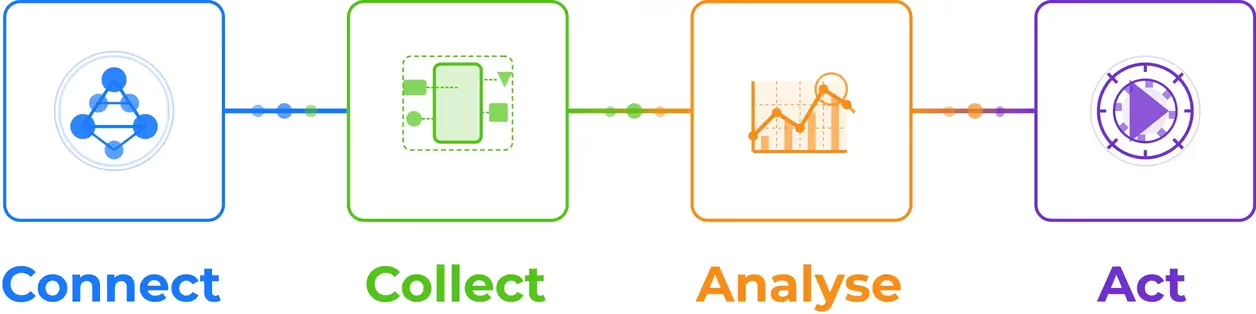

To simplify Industry 4.0, think of it as a four-step journey: Connect, Collect, Analyse, and Act.

Industry 4.0 Services

Cumulus Automation offers targeted services to help you connect systems, capture better data, and make technology work for your goals.

Unified Namespace & Data Architecture

Centralise your industrial data into a single source of truth using a Unified Namespace (UNS) model

We design scalable data architectures that break down silos, simplify integration, and make your operational data available enterprise-wide in real time.

Technology Audits

Before you start your next investment, make sure you understand your current technology stack.

A technology audit will provide you with a comprehensive report on your equipment, software stacks, protocols, interoperability, licencing costs, and end of life support. Gain recommendations on how to reduce licencing and support costs with your vendors and ensure new technology implementations will operate within your ecosystem.

IIoT & Smart Sensors

Deploy scalable smart sensors and edge devices to capture targeted real-time data from equipment, utilities, and environments.

We can help define the use case, handle device selection, network connectivity and integration—so your plant gets the data off the floor to where it needs to be.

Digital Strategy Consulting

This includes assessing your current digital capabilities, identifying priority areas for improvement, and building a practical roadmap that connects strategy to execution.

Our consulting covers everything from evaluating vendors and integration options, to defining KPIs, managing organisational change, and setting realistic timelines for transformation.

Technology Partners

Tillit is a powerful and flexible Manufacturing Execution System designed to streamline production processes, improve traceability, and connect the factory floor with business systems. Ideal for modern manufacturers, Tillit helps track production, quality, and inventory in real time.

Ignition by Inductive Automation is a leading industrial operations and SCADA platform that unifies data acquisition, control, and visualization into a single web-based solution. As a Gold Certified Integrator, we leverage Ignition to deliver scalable, secure, and real-time automation systems tailored to your operational needs.

Book a Demo With Our Team

Get Started with Cumulus Automation Now.