ERP Integration

Integrate your OT and IT systems

Get A Free Consultation

How We Connect ERP to The Plant Floor

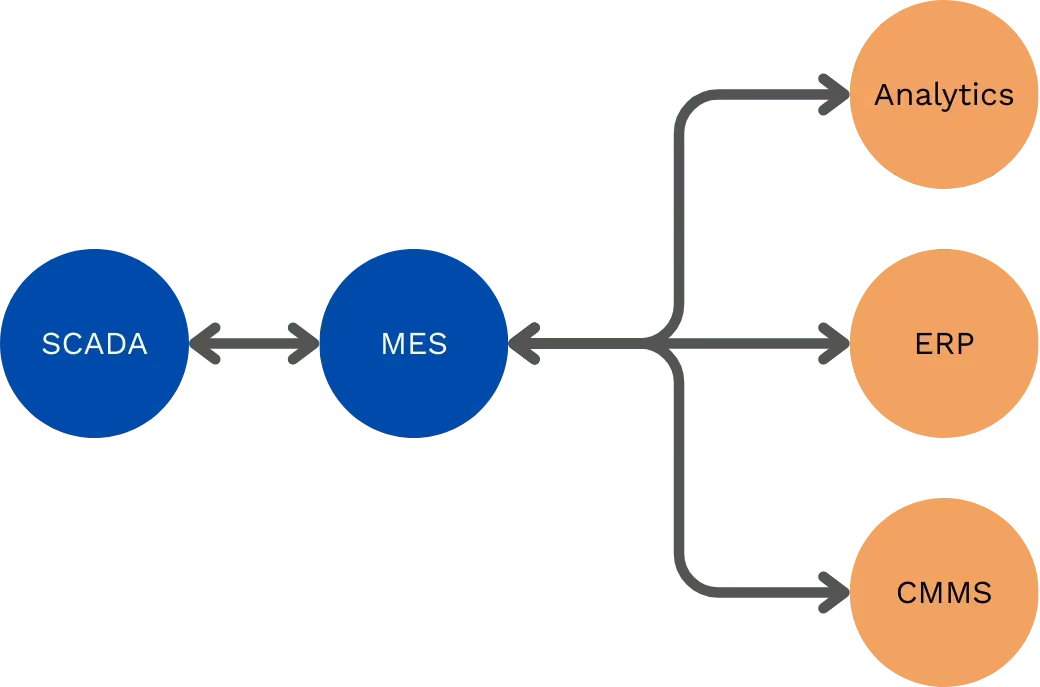

Consult with Cumulus Automation to bridge the gap between business systems and operational technology. Our ERP integration services connect higher-level functions like enterprise resource planning, maintenance management, inventory, and analytics with plant-floor systems such as MES, SCADA and data historians.

We can rapidly build integrations that are lightweight, scalable, and tailored to your operations—enabling real-time information sharing between departments and systems, reducing manual data handling, minimising errors and supporting smarter, faster decision-making. Depending on your use case, Cumulus Automation’s team can use in-built platform connectors, direct API connections, or leverage middleware workflow tools to manage complex data exchange, parsing and routing to make sure the right data connections are built, secured and maintained.

Seamless data exchange between enterprise-level and plant-floor systems to improve coordination and visibility

Flexible low-code integration architecture using middleware and accelerator tools that suit business your environment

Event-driven and real-time syncing to reduce delays using REST, OPC-UA, HTTP and MQTT data connections

Upfront design and planning to map your data model so you know exactly what's being shared and when

How Does It Work?

The data in your business is your secret weapon against inefficiency, but if your data is segregated and isolated in seperate systems, you’re not using it effectively.

The most common IT/OT integration connects your MES platform into your ERP system, creating reliable data exchange between the systems that run your business and the systems that run your production. Instead of relying on spreadsheets, emails, or double data entry, we enable systems to share information automatically based on business or production events.

Point-to-Point Integrations

Send production statistics, raw material usage, finished goods into your enterprise business layer

Send Bill of Material lists, stock inventory levels, shift schedules, planned production orders to your production management system

Enterprise Wide Integrations

Synchronise your operations, maintenance, production, reporting, and finincial tools together to create real time data flow between all elements of your business. By maintaining single-source-of-truth accuracy with seamless data exchange, you can reduce manual entry, improve accuracy and help your leaders make better decisions.

ERP Integration Best Practices

You Don't Need to Share Everything — Share What’s Important

- Start with Clear Process Mapping

Understanding how your teams actually use data day to day helps ensure integration supports real workflows—not just ideal ones. - Establish Who Owns the Data

Decide early which system is the “source of truth” for each type of data (like inventory levels or production status), and which systems should just reference it. - Build in Monitoring and Visibility

Include feedback loops so that teams can see if data is flowing as expected—and know when something’s gone wrong. - Don’t Over-Engineer

Focus on the data and workflows that actually drive decisions or cause delays, and leave the rest untouched until there’s a clear need. If an intensive manual data flow is used once per year, it’s less critical to automate than a short manual data-flow thats done everyday.

How ERP Integration Adds Value to Your Business

Eliminate Manual Data Entry Between Systems

Reduce human error and save hours of admin time by automating the flow of data from the shop floor to your business systems.Unlock End-to-End Performance Insights

See the full picture by linking operational data (like downtime, yield, and throughput) with commercial metrics like cost, margin, and delivery.Streamline Compliance and Traceability

Automatically capture and store records needed for audits, quality checks, and product recalls — without the paper trail.Synchronise Planning with Production Reality

Align production schedules, maintenance windows, and inventory movements by sharing up-to-date data between planning tools and plant systems.

Integrated Platforms Mean Fewer Errors and Faster Decisions

Book a Demo With Our Team

Get Started with Cumulus Automation Now.